Forestry Machinery Firewood Timber Processing Tool

The Manual Wood Processor Machine is an excellent solution for users who need a compact, environmentally friendly, and easy-to-operate tool for processing firewood in locations without easy access to power sources.

Make an inquiry will get the best shipping quotation

Portable manual firewood processors combine the benefits of portability, manual operation, durability, and versatility. They are perfect for homeowners, campers, or small-scale firewood processors who need an efficient, eco-friendly, and low-maintenance solution to their firewood needs. The combination of being lightweight, durable, and versatile makes these machines an excellent choice for those looking to process wood efficiently without the need for external power or large investments.

The portable manual firewood processor is a practical and versatile tool for small-scale firewood processing:

1. Portability

Compact and Lightweight: These firewood processors are specifically designed to be easily moved from one location to another. Typically lightweight and small enough to fit in a vehicle, they can be transported to remote locations, ensuring you can process wood anywhere you need it, whether in your backyard, on a campsite, or at a cabin in the woods.

Wheels for Mobility: Many models are equipped with wheels or handles, making it easier to move the processor across different surfaces. This added feature significantly enhances mobility, whether you're working on uneven terrain or just need to relocate the machine to a different part of your property.

2. Manual Operation

Levers and Hand Cranks: Manual firewood processors are powered entirely by human effort. Levers or hand cranks are used to operate the cutting and splitting mechanisms. This reliance on manual labor allows users to have full control over the process and eliminates the need for external power sources like electricity or gasoline.

Low Operating Costs: Since these machines don’t require fuel or electricity, operating costs are minimal. This makes them an attractive option for those who don’t want to deal with the complexity or expense of powered machines.

Eco-Friendly: No emissions, no fuel consumption. Manual operation is an environmentally conscious choice, reducing your carbon footprint compared to motorized or gas-powered alternatives.

3. Durability

Sturdy Construction: These processors are built to withstand the rigors of outdoor use. They are usually made with heavy-duty materials such as steel or other durable metals that can endure wear and tear, harsh weather, and rough handling.

Weather-Resistant: Many models are designed with outdoor elements in mind, meaning they are often rust-resistant or coated with protective finishes to keep them functioning well over time, even in challenging environmental conditions like rain, snow, or extreme sunlight.

Long Service Life: Despite their manual operation, the durability of these machines ensures that they can last for many years with proper maintenance, making them a sound investment for those who regularly process firewood.

4. Versatility

Cutting and Splitting Functions: Most manual firewood processors are designed to both cut and split logs, offering versatility in how the wood is processed. Whether you need to cut logs to length or split them into smaller pieces for burning, these machines allow you to handle both tasks without needing multiple tools or machines.

Affordable: For users on a budget, a manual firewood processor offers a cost-effective solution compared to larger, motorized machines. It allows homeowners, small-scale firewood gatherers, or those just needing firewood for personal use to handle a variety of tasks at a lower cost, without sacrificing performance.

Adjustability: Many models allow you to adjust the cutting and splitting settings, providing flexibility in the size of the firewood you need. This means you can process firewood in a range of sizes, from smaller kindling to larger logs, based on your requirements.

| 15T Manual Firewood Cutting Processor | |

| Power | 15HP |

| Weight | 500KG |

| Max log Dia | 40cm |

| Max log length | 55cm |

| Saw motor with bearing | 36L/ min,4800rpm |

| Chain saw | 18"Stihl |

| Cylinder bore | 3.2inch |

| Cycle time | 7s |

| Wheel | 12 inch high speed trailer wheel |

| Knife | 4 ways ( optional 6 ways ) |

| Packing | 1 pcs/ 1 pallet |

| 40"HC container | 22 pcs |

Product detail description

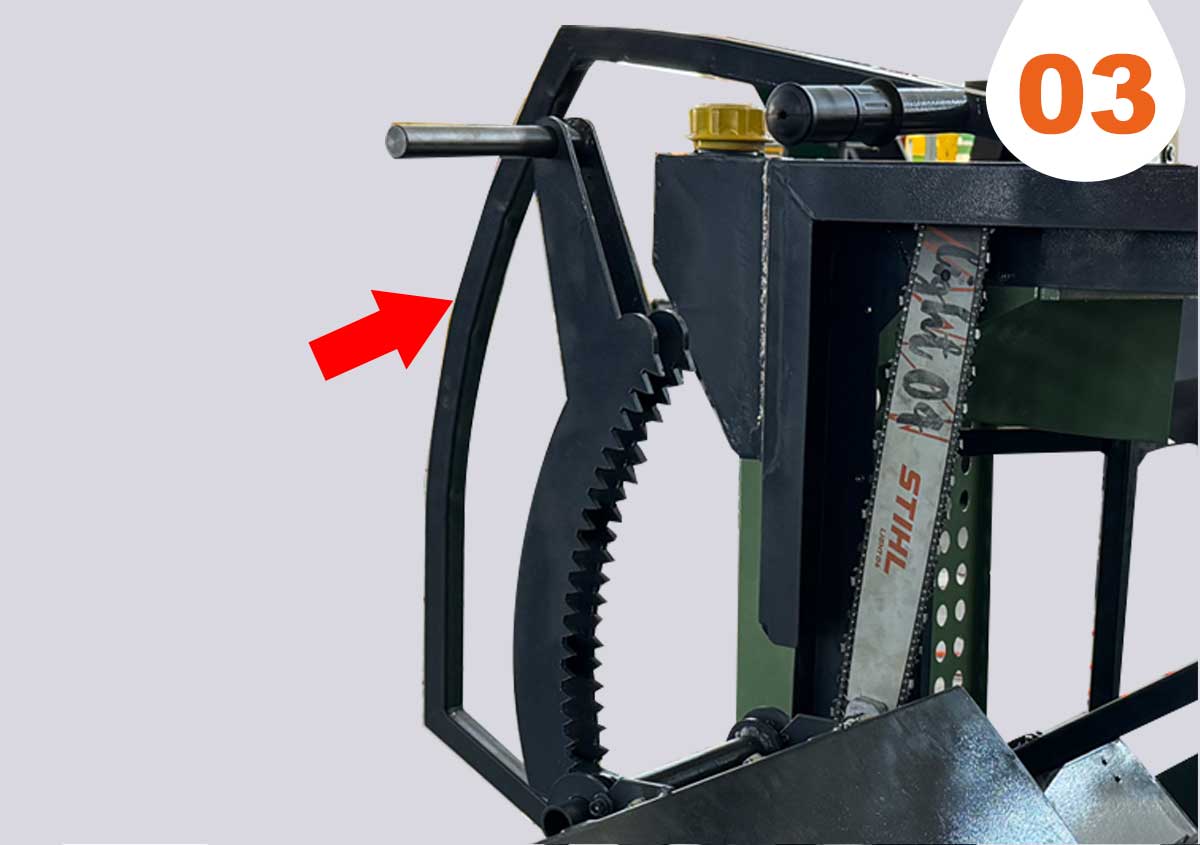

Log Positioning is a crucial aspect of the manual firewood processing workflow, especially when using a portable manual firewood processor. Proper log positioning ensures safe, efficient, and accurate cutting and splitting of the logs.

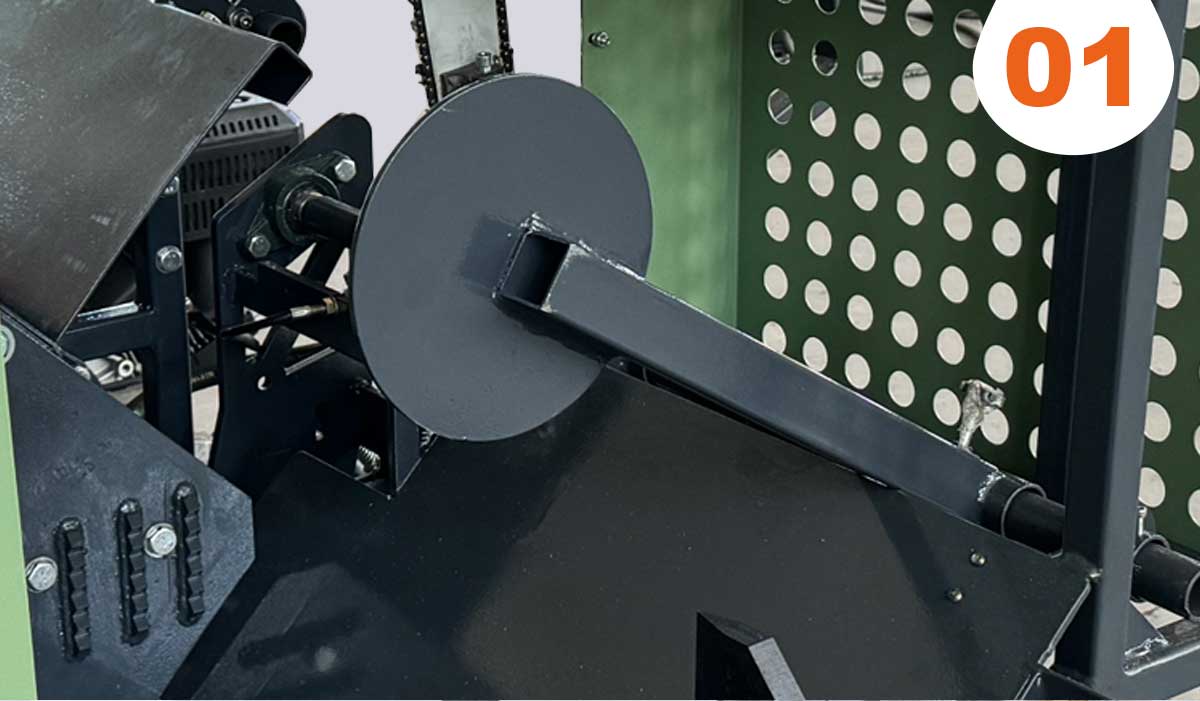

Log Clamping is an essential feature in firewood processing machines, including portable manual firewood processors. Clamping secures the log firmly in place during cutting or splitting, improving safety, precision, and efficiency.

The saw handle is a critical component of a manual firewood processor, especially for models equipped with a cutting mechanism that includes a saw. It provides the user with control, stability, and comfort during operation.

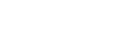

A feed conveyor system is an essential component in many firewood processors, designed to efficiently transport logs from the loading area to the cutting or splitting mechanism. In a manual firewood processor, a feed conveyor is often simple yet effective, enabling smoother operation and reducing the physical effort required for handling logs.

Both 4-way and 6-way are supported

Finished product display

Product multi-directional display

Make an inquiry now and receive a FREE product brochure loaded with vital product information and creative inspiration. Join us at JIERUI Machinery Equipment Co., LTD to elevate your operations and experience the future of machinery!

Related Products

Related News

Submitted successfully

We will contact you as soon as possible