Forestry Machinery 50T Industrial Firewood Splitter Machine

Max Log Diameter: 800mm

Splitting Capacity: Can split up to 28 pieces per log.

High Productivity: Processes large logs quickly, with automated feeding and splitting.

Heavy Duty: Built for industrial-scale wood processing, possibly with hydraulic lifting and transport systems to speed up workflow.

Make an inquiry will get the best shipping quotation

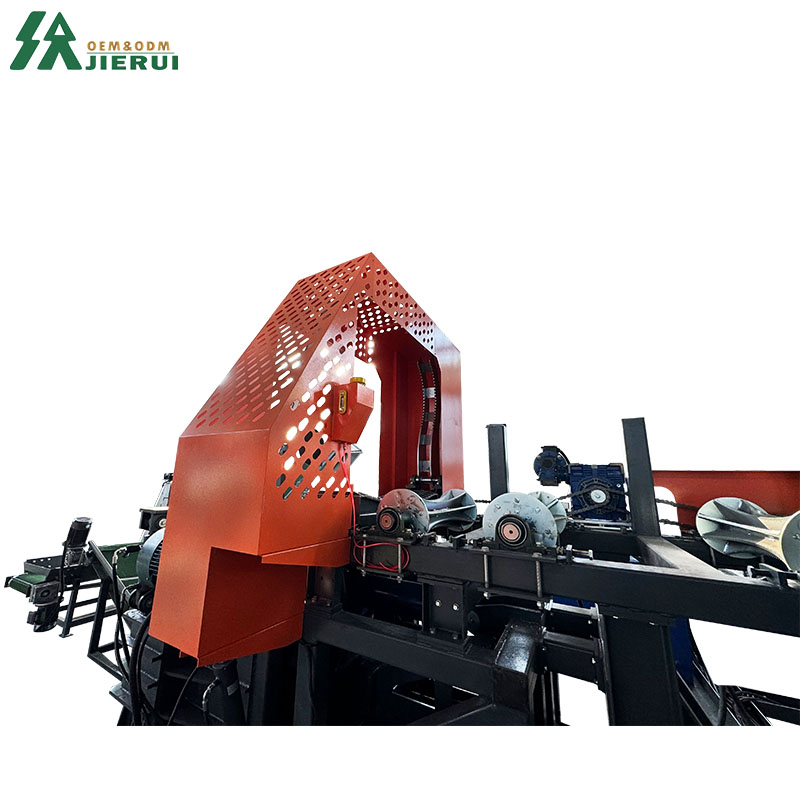

High-capacity JR50T automatic wood processor, which is capable of dividing individual logs into up to 28 pieces, with a maximum log cutting diameter of 8000 mm, this machine appears to have been built for industrial use, possibly in environments where large-scale wood processing is required. Automated features allow for faster and more consistent wood splitting, reducing manual labor and increasing overall productivity.

The JR50T is a highly effective commercial fire wood processor designed to increase productivity while reducing labor costs and physical strain on operators. With its high efficiency, consistency, labor savings, and time savings, it offers a strong solution for businesses involved in large-scale firewood production. Whether you’re looking to increase output, reduce manual labor, or improve the consistency of your product, the JR50T offers a powerful and reliable machine that can help streamline the entire process.

1. High Efficiency

Automated Cutting and Splitting: The JR50T's automation significantly reduces the need for manual labor, which speeds up the entire production cycle. With advanced hydraulics and mechanized systems, the machine can quickly cut and split logs, making it ideal for high-volume operations.

Optimized Workflow: By handling multiple stages—cutting, splitting, and sometimes even stacking or conveying firewood—the JR50T minimizes delays and idle time, leading to a consistent output rate.

2. Consistency

Uniform Firewood Size: One of the standout features of automatic firewood processors like the JR50T is their ability to produce consistent, uniform splits. This is particularly important for commercial firewood sales, where uniformity ensures that the firewood is easy to stack, transport, and burn.

Precision in Splitting: Thanks to precise hydraulic controls, the JR50T can achieve highly accurate splits with minimal variation. This leads to less waste and more usable firewood from each log.

3. Labor Savings

Minimal Manual Intervention: Once the logs are loaded into the machine, the JR50T takes over the splitting and cutting process. Operators can monitor the process from a single control station, reducing the physical effort required and allowing them to oversee the entire production line.

Less Fatigue for Operators: With the JR50T doing the heavy lifting, the operators experience significantly less physical strain, which is important for long hours of work or large-scale operations. This ultimately boosts overall productivity since workers can maintain focus for longer periods.

Potential for Fewer Staff: Due to the automation, the need for a large workforce is reduced. In some cases, a single operator can manage the entire process, cutting down on staffing costs and simplifying operations.

4. Time Savings

Reduced Setup and Operation Time: The JR50T likely has quick setup features, meaning it can be ready for use in less time. The automation of tasks such as log feeding, cutting, and splitting eliminates the need for operators to perform these manually, freeing up time for other critical tasks.

Faster Processing Speed: Because the JR50T operates quickly and efficiently, it processes logs much faster than traditional methods, such as manually chopping or splitting wood with a chainsaw and axe. The speed of production increases, and time spent on each log is minimized.

Increased Throughput: The combination of speed and automation leads to a substantial increase in the total volume of firewood processed in a given time frame. This allows businesses to scale operations and handle larger workloads.

Model |

Give you more reasons to choose

Details show quality

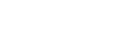

The control panel of the JR50T Automatic Firewood Processor is designed to streamline operations, enhance safety, and maximize productivity. With features like intuitive controls for feeding, cutting, splitting, and sorting, as well as real-time diagnostics and system alerts, operators can manage the entire firewood production process with ease and precision.

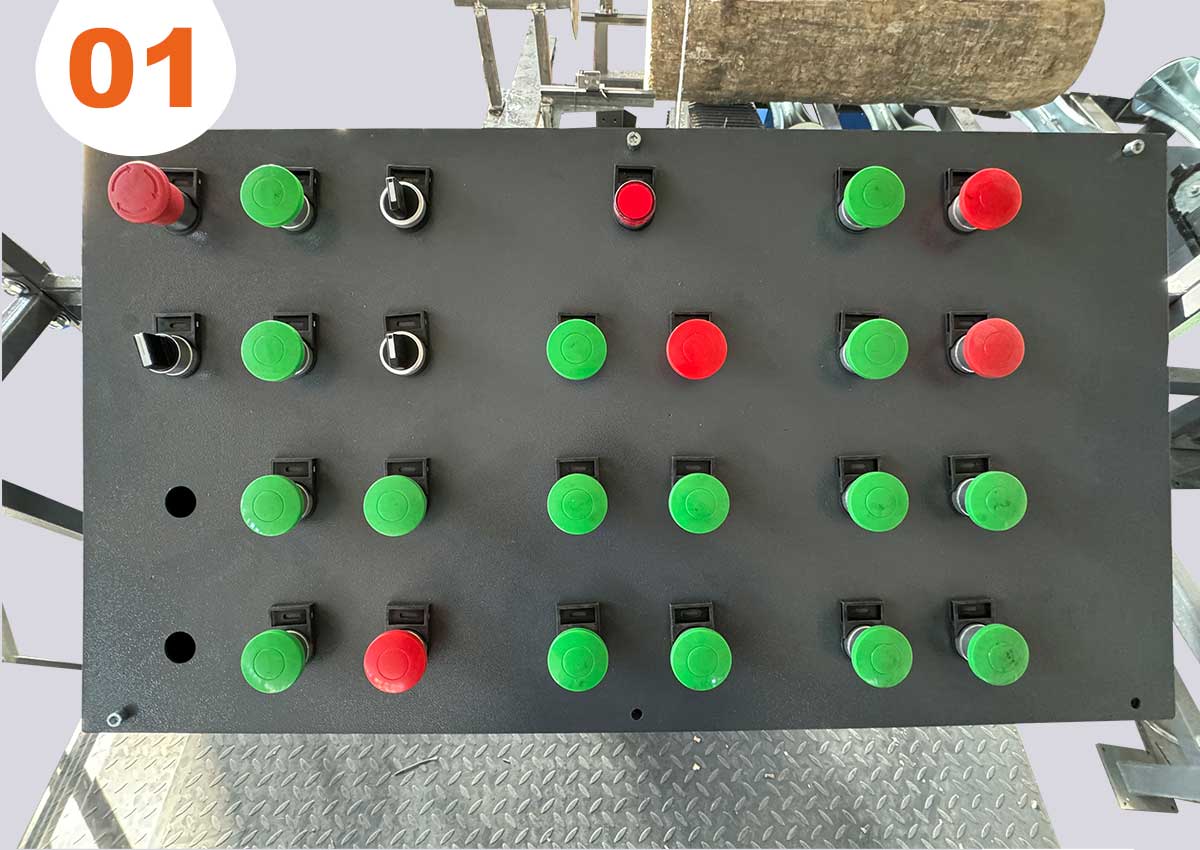

The JR300 Log Table plays a crucial role in enhancing the overall efficiency of an automatic firewood processing system. Its ability to feed, position, and sometimes even sort logs before they are sent to the saw and splitter helps streamline the entire process, boosting productivity while reducing manual labor and downtime. With robust construction, automatic feeding capabilities, and a focus on safety, the JR300 Log Table is an essential component in modern firewood production systems.

28-way supported

Splitting logs into 28 pieces at once drastically reduces the amount of time and energy needed compared to processors with fewer wedges (e.g., 4-way or 6-way). It also speeds up the overall processing time.

Conveyor

The conveyor is an essential part of the log processing system, particularly in automatic firewood processors like the JR50T and other similar machines. It is used to move the cut or split firewood from the processing area (such as the saws or splitters) to a fixed location on the ground, where the wood can be stacked, sorted, or prepared for further use or distribution.

Chain saw

Before splitting them into firewood, the chain saw plays a key role in efficiently cutting the logs to the desired dimensions.

More details

Company Profile

Shandong JIERUI Machinery Equipment Co., Ltd. is the world's leading manufacturer of high-quality sawmills. Focusing on production and research and development, the company serves a wide range of industries and currently serves more than 12,000 businesses worldwide. The products have been successfully exported to 61 countries.

The company's products include log sawing equipment, solid wood furniture processing machinery and wood splitting equipment. Shandong Jeri's commitment to standardized quality management and excellent customer service has won the trust and loyalty of global customers, positioning it as the world's top sawmill supplier.

In addition to maintaining a strong commitment to excellence, Shandong Jeri actively pursues technological innovation and strives to accelerate the development of advanced sawmills. Through continuous improvement of its products and services, the company aims to provide the best sawmill production line solutions to meet the changing needs of its global partners.

Customer visit

Make an inquiry now and receive a FREE product brochure loaded with vital product information and creative inspiration. Join us at JIERUI Machinery Equipment Co., LTD to elevate your operations and experience the future of machinery!

Related News

Submitted successfully

We will contact you as soon as possible